Without HACCP, the case might not be!

The implementation of the HACCP system is a necessary step in the framework of the economic integration of the domestic food industry into the European and world markets, ensuring the hygiene of food industry enterprises. The HACCP system implemented at the enterprise provides it with such advantages as a systematic approach to product safety and the ability to move from responding to the consequences of food safety incidents to systematic prevention of these incidents. A significant technical and commercial advantage of a successfully operating HACCP system is also the possibility of its integration into any recognized product quality assurance system. Therefore, the presence and effective functioning of the specified system is not the only necessary condition for the compliance of the production facilities and the food products produced on them with internationally recognized requirements.

About the introduction of HACCP systems, in the dry language of regulatory documents

The final provisions of the Law of Ukraine “On Amendments to Certain Legislative Acts of Ukraine Concerning Food Products” define the terms of development, implementation and application of permanent procedures based on the principles of the system of analysis of dangerous factors and control at critical points. It is foreseen that the new edition of the Law of Ukraine “On Basic Principles and Requirements for the Safety and Quality of Food Products” stipulated by the Law of Ukraine requires the introduction of the HACCP system for facilities that carry out activities with food products that contain raw ingredients of animal origin (except small facilities), enter into force from September 20, 2017. Also, for facilities that carry out activities with food products that do not contain raw ingredients of animal origin (except for small facilities), the introduction of the HACCP system from September 20, 2018, and for all small capacities from September 20, 2019.

It should be noted that the implementation of food safety management systems “Hazard Analysis and Critical Control Points – HACCP” in Ukraine has been going on for more than a decade. The specified systems are effective from the point of view of maximally guaranteeing the safety of food products, including products of animal origin. Several relevant national standards of Ukraine have also been put into effect. First of all, they include DSTU (State Standarts of Ukraine (Derzhavni Standarty Ukrainy) 4161-2003 “Food safety management systems. Requirements”, DSTU ISO 22000:2007 “Food safety management systems. Requirements for any food chain organizations” and DSTU ISO 22005:2009 “Traceability in feed and food chains. General principles and basic requirements for the development and implementation of the system”. In 2010, the Chief State Inspector of Veterinary Medicine of Ukraine issued an order according to which managers and owners of facilities engaged in the production or distribution of food products are required to implement a departmental control system based on the principles of HACCP. The Ministry of Agrarian Policy and Food of Ukraine, by an order issued in 2013, introduced the obligation to implement and apply permanent procedures based on the Food Safety Management System principles. The order stated that in case of non-fulfillment of its requirements, the activity of the food production enterprise may be terminated, and the enterprise may be repurposed. In order to encourage producers and sellers (suppliers) of food products, it was supposed to speed up the implementation of HACCP systems or other systems for ensuring the safety and quality of food products. By the decision of the Chief Sanitary Doctor of Ukraine, it was allowed to halve the frequency of inspections of those enterprises where the mentioned systems have been successfully implemented and used.

The long-standing practice of implementing the HACCP system at enterprises of the food industry, including the meat processing industry, gives reason to assert that, under conditions of voluntariness and non-obligation, our manufacturers and other market operators are in no hurry to arm themselves with a globally recognized food product safety tool. According to the information of the Department of Food of the Ministry of Agrarian Policy and Food of Ukraine, as of January 1, 2016, 279 domestic enterprises have already implemented the HACCP system, and 91 enterprises are currently working on the development and implementation of the specified system. Thus, only about 20% of food and processing industry enterprises have implemented HACCP systems, and of the total number of food industry enterprises that have already implemented them, 20.5% are meat processing enterprises. Safety management systems under DSTU ISO 22000:2007 “Food Safety Management System. Requirements for any organizations of the food chain” as of January 1, 2016, have already been implemented at 438 enterprises of the food industry, and the development and implementation of the specified system are currently being carried out at 77 enterprises, that is, 26% of all enterprises of the food and processing industry have implemented safety management systems, harmonized with international ones, or are at different stages of implementation of the specified ones.

Great-profile enterprises in the meat industry have already successfully implemented product safety and quality management systems. On the other hand, small meat processing enterprises, for obvious reasons, the main of which are limited financial capabilities, insufficient qualification of employees, and lack of organizational and methodological preparation, delay the implementation and application of constant operating procedures based on the principles of the system of analysis of dangerous factors and control at critical points. Indeed, the law will not require the mandatory availability of these systems at small businesses until September 2019, but this date is not so far away. And considering the small prospect of a significant improvement in Ukraine’s economic situation in the near future, it is expedient to carefully think through and plan the necessary measures and expenses today. On the other hand, all measures should be taken to ensure that the state’s active participation in the implementation of the HACCP system and other similar systems at food industry enterprises through a number of laws and other regulatory documents takes place in compliance with the principles of deregulation, that is, without increasing administrative pressure on producers. All over the world, HACCP systems are implemented to achieve the highest possible level of food safety for the health and life of consumers while simultaneously simplifying control measures and minimizing the costs of implementing these systems. Instead, in domestic conditions, there is a tendency not to simplify but to complicate the safety control system, which consists of an excessive number of prerequisite programs, unjustified designation of control points, efforts to spread the validity of HACCP plans for product quality control, etc. Unfortunately, this is often the fault of specialized organizations and firms that implement quality and safety management systems at enterprises and, at the same time, compensate for the lack of a carefully and responsibly performed risk analysis with excessive strictness of control.

For small businesses, the costs of work associated with the implementation of HACCP will be significantly lower but not so insignificant as not to bother our manufacturers. It is important that the state, having established the rules and terms of implementation of the HACCP system at food enterprises, does not remove itself from the problems associated with this process. Perhaps a mechanism of financial assistance to owners of enterprises that implement safety management systems should be provided. And it is undoubtedly necessary to provide comprehensive (free!) methodological assistance to those enterprises that, in full accordance with the Law of Ukraine, develop and implement the HACCP system by themselves.

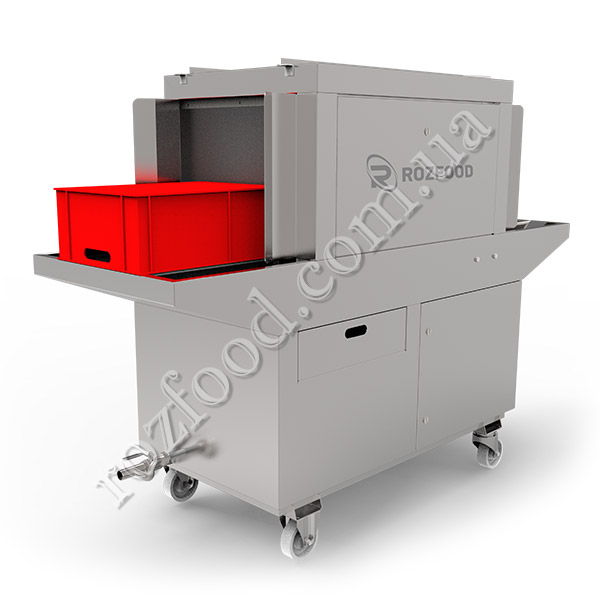

Manufacturers should realize that the HACCP system implementation is a necessary step in the economic integration of the domestic food industry into the European and world markets. The HACCP system implemented at the enterprise provides it with such advantages as a systematic approach to product safety and the opportunity to move from responding to the consequences of food safety incidents to systematic prevention of the ones. A significant technical and commercial advantage of a successfully operating HACCP system is the possibility of its integration into any of the recognized systems for product quality assurance. Therefore, the presence and effective functioning of the specified system is not the only necessary condition for the compliance of production facilities and food products produced on them with internationally recognized requirements. Machines for washing boxes or containers are important elements for successful HACCP implementation.

Experienced manufacturers often express their misunderstanding of the need to implement HACCP systems instead of the domestic systems of sanitary and production control that are used and tested in practice. According to the experts, compliance with the production control instructions and thorough execution of all the checks provided for by it completely guaranteed the safety of food products. Indeed, the implementation was guaranteed, it required the availability of appropriate technical means and the involvement of numerous personnel. Conceptually specified systems belonged to the inspection control systems of raw materials and materials, their transformations during production, packaging, storage, and distribution. Inspection control systems are reliable but inefficient and too expensive. The mentioned shortcomings prompted to find a new solution to the problem, which was the HACCP system implementation at food enterprises. World practice shows that the vast majority of problems with the safety of food products are caused by the unsatisfactory quality of raw materials and improper modes of its technological processing, unauthorized changes to recipes established by the technological documents, non-compliance with the requirements for sanitary conditions of personnel, which is ensured by the hygiene station, technological equipment, and production premises. That is why the conceptual core of the HACCP system is a thorough analysis of probable biological, chemical, and physical risk factors, thanks to which the possibility of incidents occurring at the established control points is consistently minimized. At one time, food enterprises of EU countries and other world advanced countries went through the procedure of implementing the HACCP system or other ongoing procedures based on the principles of the food safety management system. The effective spread of these systems was significantly facilitated by the presence of many enterprises with the GMP (Good Manufacturing Practice) system. Its rules and norms provide the implementation of preventive measures to identify the risk factors inherent in a specific production. At the same time, the presence of an implemented GMP system cannot significantly speed up the term of HACCP system implementation. Usually, the specified procedure at a meat processing of medium capacity enterprise can last up to two years due to the need to develop and implement monitoring systems, record results, determine the form and range of corrective actions, introduce a documentation system at workplaces, etc.