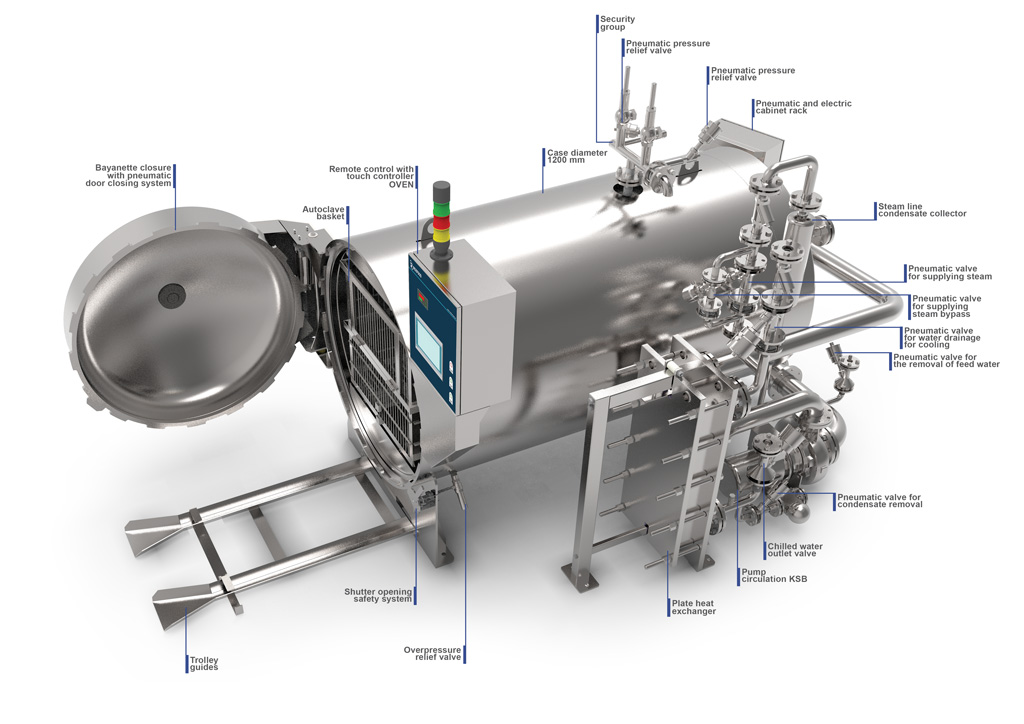

Modern horizontal autoclave. The new model complies with all the rules for the safe operation of equipment, which is operating under high pressure and also complies with the EU technical operational standards.

A double-circuit heating-cooling system, as well as a powerful circulation pump, provide optimal operating temperature conditions, as it is equipped with a plate-type heat exchanger (reduces water consumption) with high efficiency, so this allows you to connect the autoclave to the production water exchange system and obtain the most effective temperature regulation indicators.

Due to the effectiveness of the suffocating system, the process of temperature acceleration and cooling of the product occurs evenly along the entire length of the autoclave, quickly and efficiently.

Operation is controlled by a touch screen, controlled by an industrial computer, which can store sterilization programs and histories of previous cycles.

The interface of the management program is distinguished by a high level of “usability”, a sequence that accelerates the learning process and ease of use. The autoclave is equipped with a three-level safety system, which makes it impossible to open the door if there is excess pressure inside the equipment.

The control system provides for both short-term and long-term power failure, and after its restoration, the system automatically adjusts the product processing program. It`s made of AISI 304 stainless steel. The body is covered with mineral wool and lined with a sheet of stainless steel to provide thermal insulation. Registration of pressure and temperature in the autoclave is carried out automatically and recorded on the memory stick. Control of system safety parameters during sterilization is carried out synchronously electrically, mechanically, and pneumatically.

The capacity – 2 baskets

The heating type – steam/electric

The material is food-grade stainless steel, acid-resistant AISI 304

The working volume – 2.5 m3

The autoclave working pressure – 0.3 MPa

The working temperature of the environment is no more than 145 ˚С

Power, kW – steam: up to 5; electricity: up to 240

Steam supply, kg/hour – 600; steam consumption per cycle, kg – 250; steam pressure, Bar – 4-6

Consumption of cold water, m3/hour – up to 3

Raspberry Pi4 controller, automation of “Miсrol” TM

The number of stored programs – up to 60 pcs

The duration of the cycle – 20-25 minutes. to the sterilization mode, the duration of sterilization depends on the product being processed, cooling — ~30 min (up to +30°С). The quality of water at the entrance is potable water

The temperature of the cooling water in the cooling mode – 110 … 30 ° C

Discharge of water from the heat exchanger can be carried out both into a separate sewage system and into the HW system of the enterprise.

The electrical equipment protection class – IP54

Basket dimensions (LxWxH), mm – 980x780x800 mm

The capacity of cans in the basket is calculated according to the size of the can provided by the client

Case diameter, mm – 1200 mm

Weight, kg – 2050